Welcome!

Industar e-shop

All prices include VAT *

EWM Picomig 225 puls TKG MIG/MAG welding machine (semi-automatic)

EWM_Picomig_225_puls_TKG_operator_manual.pdf

EWM_Picomig_225_puls_TKG_manual.pdf

EWM_Picomig_225_puls_TKG_data.pdf

EWM provides an innovative welding process to its customers.

As a technology leader, EWM has been researching and developing equipment for decades to make welding even easier, more economical and, above all, more reliable for customers. By doing this, the manufacturer of EWM machines checks and analyzes the components of individual welding equipment and the complex interaction parameters in working conditions, guaranteeing optimized quality throughout the welding process.

ForceArc pulse XQ - forceArc pulse is a MIG/MAG welding process with a heat reduced pulse arc. Easy to use and suitable for the entire performance range for welding non-, low- and high-alloy materials.

It is characterized by an excellent gap connection even in the high performance range and allows controlled welding with up to 4 mm of variable air gap between the parts to be welded.

ForceArc pulse - for the best steel and stainless steel welding ever with incredible cost savings!

Advantages of ForceArc pulse:

Higher welding speed,

Symmetric seam formation and maximum possible seam thickness (a-dimension) for seams

Excellent penetration

Deep, concentrated penetration with reliable root weld penetration,

Practically, welding takes place without spatter,

Minimization of post-weld processing,

Even for sheet metal with a scaled or heavily contaminated surface

Healthy work for welders,

Low load for the welder at the workplace,

Less welding fumes,

Quiet, pleasant sound of arc welding,

Easy to use interface!

The ForceArc pulse welding® process has up to 15% lower heat output in the upper power range compared to pulse. This results in less twisting and warping of parts.

Other benefits:

Reduced heat energy,

The occurrence of deformations, welding defects,

Fewer parts after processing (straightening, grinding, cleaning)

Less burning of alloy elements and, therefore, higher resistance to corrosion (alloying elements do not burn during welding)

Force Arc pulse for welding high alloy (CrNi) steels compared to forceArc arc:

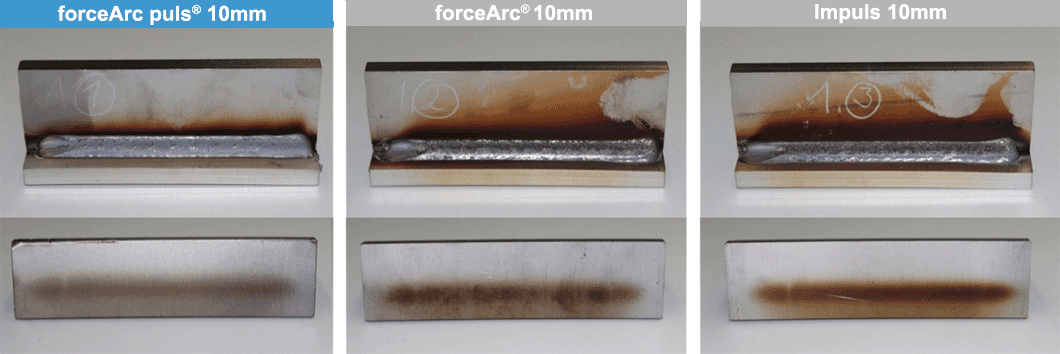

Melt comparison between forceArc pulse®, forceArc® and pulse arc:

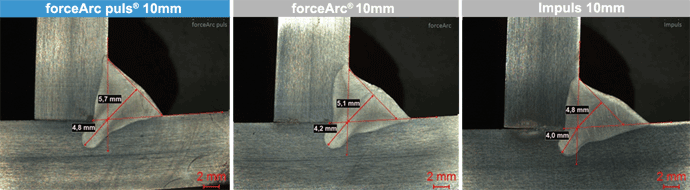

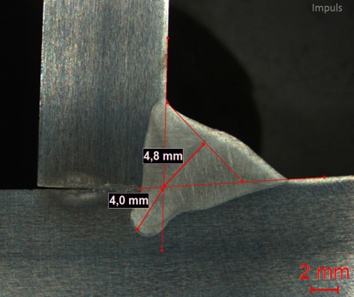

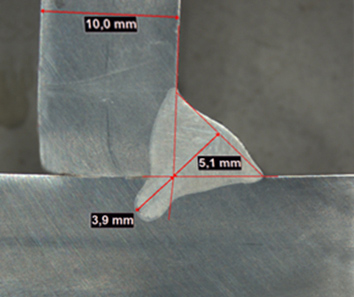

Pulse Vs = 45 cm/min, a=4.8 mm and forceArc puls® Vs = 60 cm/min, a=5.1 mm comparison of welding penetration:

Advantages for your benefit:

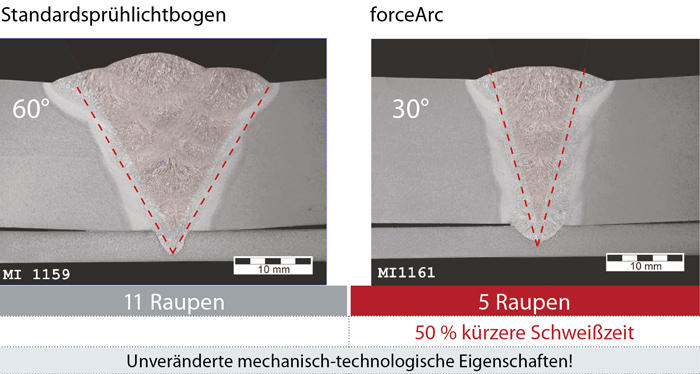

Smaller seam opening angle deep penetration,

Reduction of welding layers (interlayer defects - non-fuse between layers)

Less distortion due to heat reduction, concentrated l welding arc.

Excellent root and side detection

Perfect welding even with high welding wire protrusion,

Reduction of penetration notches, incisions

Practically splash-free,

Perfect application for wagons, bridge structures and steel structures.

Non-alloyed, low-alloyed and high-alloyed steels, as well as high-strength fine-grained steel

Perfect penetration of the root suture.

forceArc / forceArc pulse

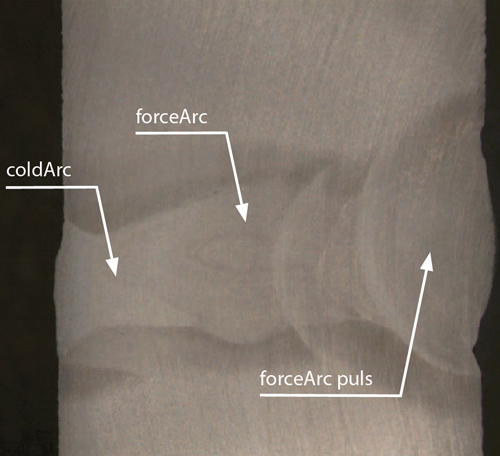

A combination of ForceArc pulses, forceArc and coldArc

Root layer with coldArc, intermediate layers with forceArc and top layers with forceArc pulses

Savings in welding layers due to a smaller opening angle

Perfect ignition and crater filling with forceArc pulses, forceArc welding

Less material distortion due to less heat input,

Lower interlayer temperature and minimal structural changes

Particularly advantageous, for example, when welding fine-grained structural steels

Reduced angular shrinkage in root sutures.

Welding steel: S 235; 20 mm

Welding protection: M21 - ArC - 18

Wire type and diameter: 1.2 mm G4Si1

Weld seam layers 4

Position: PC (horizontal seam)

Opening angle: 10°

Welded on one side, without abutment.

Combination of ColdArc, forceArc and forceArc pulses.

Economic welding, cost savings:

Total cost savings of up to 60%

Minimized weld preparation

Fewer layers

Less filler and inert gas consumption

Reduced welding time

Especially beneficial for dynamically loaded welding parts.

Metal steel: S 355; 30 mm

Gas: M21 - ArC - 18

Wire type and diameter: 1.2 mm G4Si1

Weld seam layers: 11

Position: PB / PA (bottom, horizontal)

Opening angle: 25°

Welded on one side, without abutment. with forceArc

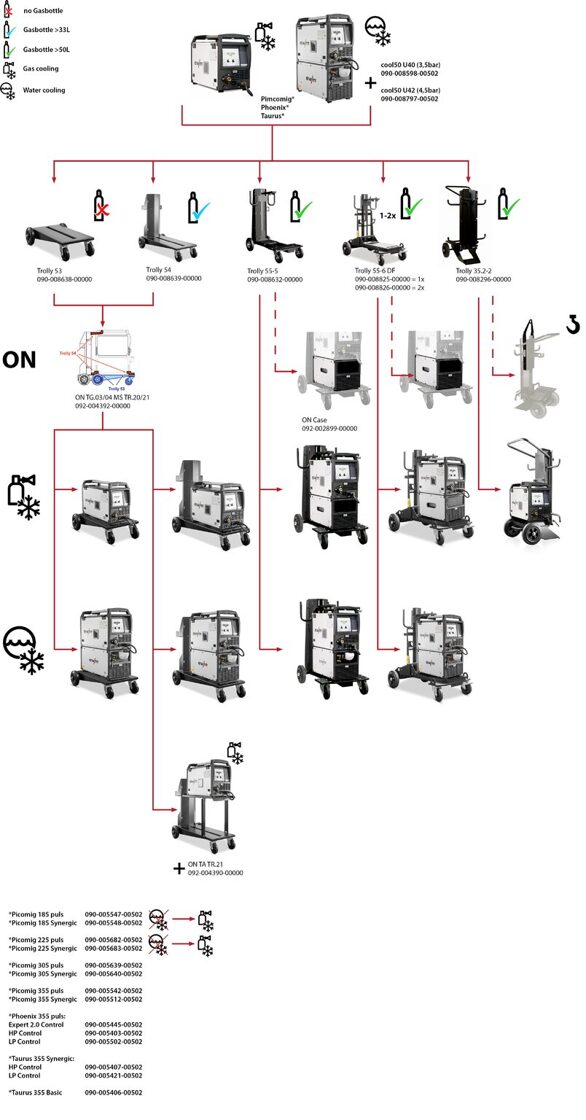

Cart

Cart is empty.