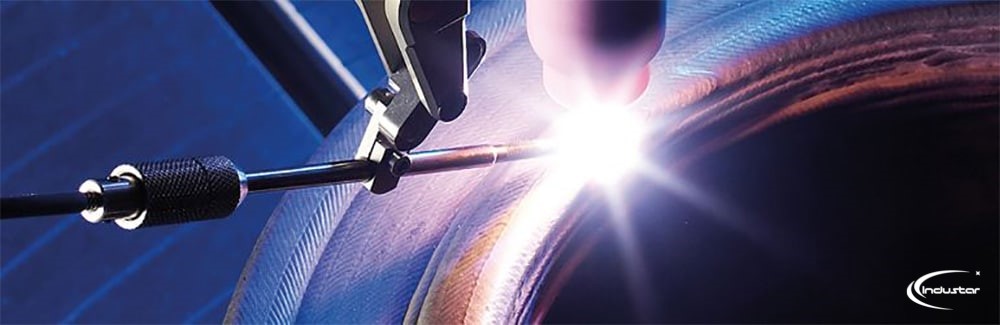

How is orbital welding performed?

The orbital movement of the welding head is fully automated, as well as all other accompanying technological operations. The length of the welding arc is preset by firmly fixing the head at the desired height above the surface of the pipe.

The orbital welding process takes place under the control of a processor controlled by a special program in which all parameters are recorded. The program settings take into account the changing welding conditions as the electrode moves along the orbital path.

The weld along the perimeter of the welded pipe is divided into sectors in which the process parameters have a constant value. Thus, the circular "orbital" seam is divided into horizontal parts (floor and ceiling), vertical (with movement down and up) and sections located at a certain angle.

Depending on the orientation of the seam and the direction of movement of the welding head, the programmed values of the following parameters are automatically set in each sector:

the speed of movement of the welding head with the electrode;

welding current values;

filler wire feed speed;

the amount of shielding gas delivered per unit of time.

Thanks to the exact observance of the parameters of the welding mode, a uniform seam of the same quality is formed in each of the orbital sections along the entire perimeter.

Application

In addition to performing welding work during the installation of trunk pipelines, the orbital welding method is successfully used in the workshops of companies that constantly perform connections of large-scale pipe elements.

Such companies include pipe factories that assemble structures from pipes and fittings, as well as manufacturers of boiler equipment.

The application of orbital welding methods in energy and shipbuilding is effective. The quality requirements for stainless steel pipe joints in the food industry are particularly high, and in this situation orbital welding technology is the best solution.

It is possible to use this technology in the installation of main and distribution pipelines of urban engineering communications. The device successfully copes with the welding of very small diameter pipes.

The high stability of the parameters, the absence of errors related to the human factor in some cases make this welding method the only one capable of providing the required level of quality.

Carrying out one type of orbital welding operation on pipes of the same diameter provides a particularly significant benefit, as the machine does not need to be reconfigured for another process and productivity gains are maximized.

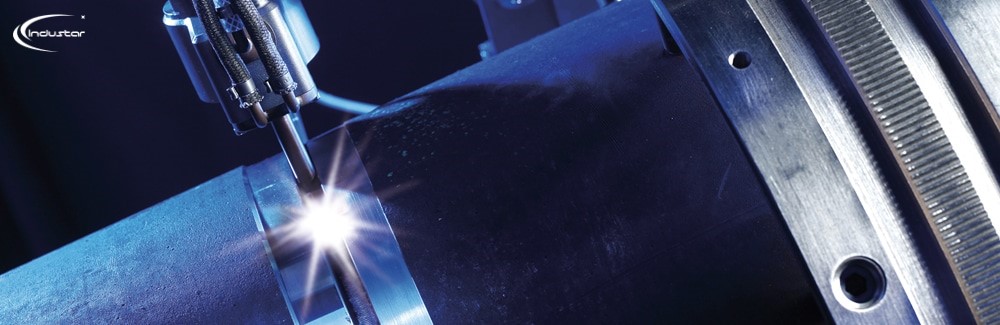

Main equipment components

welding head, which holds the torch and determines its movement along the seam;

welding current source, which is an inverter converter;

programmable controller and actuators for controlling process parameters (gas supply valve, filling wire pulling mechanism controls);

burner liquid cooling system.

The welding head device can be made in two ways: open and closed. With an open type head, the process is similar to a manual one using a tungsten electrode.

In this case, argon simply flows from the torch with a certain pressure to the welding site. The closed head is isolated from the surrounding area by a special chamber filled with argon.

The inverter power supply is the most suitable for organizing the control of the welding current program.

The practical implementation of the control program and the conversion of codes into specific control pulses is carried out by a specialized controller.

Considering the fact that the automatic welding process is continuous, it is necessary to cool the parts of the torch that are in the immediate vicinity of the arc discharge. For this purpose, a special system has been created that ensures the forced circulation of coolant through the cooling circuit.

The welding system can be equipped with a remote control, which provides the operator with the opportunity to intervene in the process if necessary. Thus, automation makes it possible to simplify the welder's work as much as possible.