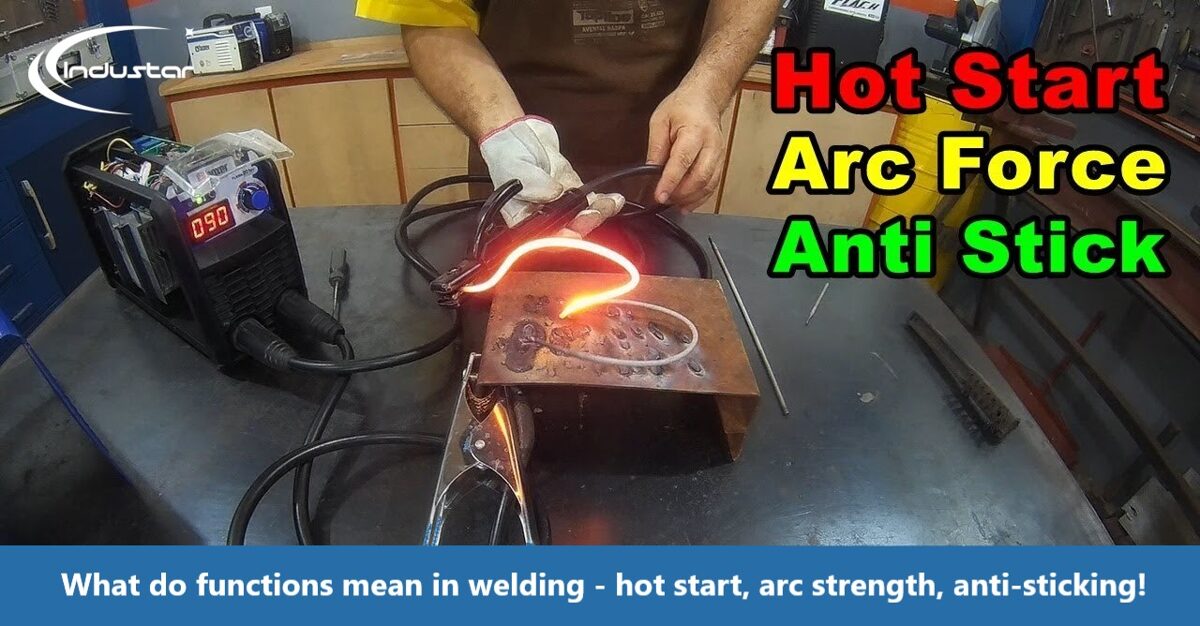

Very simple! What do functions mean in welding - hot start, arc strength, anti-sticking?

When choosing a welding inverter, we usually pay

attention to the main parameters of the device, such as: the power of the

device, and therefore the maximum welding current with which the inverter will

work; time during which the inverter will be able to operate without shutdown

at maximum current; maximum electrode diameter, minimum welding current (when

working with thin metal); device size, weight, etc.

When choosing a welding inverter, we usually pay

attention to the main parameters of the device, such as: the power of the

device, and therefore the maximum welding current with which the inverter will

work; time during which the inverter will be able to operate without shutdown

at maximum current; maximum electrode diameter, minimum welding current (when

working with thin metal); device size, weight, etc.

These all seem to be familiar and well-known concepts.

However, recently, more and more often, when reading the instructions for the

welding equipment or the description of the inverter on the Internet, we come

across such concepts as: "hot start (Hotstart), arc force (Arcforce or Arcforsing),

anti-stick function (Antistick). Let's try to find out what these concepts are

and how they help (and maybe hinder...) the welding process.

What is a "hot start"?

Hot start, hot start is the same concept. What does this feature mean? In short, it is an additional welding current surge at the moment when the electrode touches the workpiece. For example, if we have a welding current of 150 amperes, then when the electrode is touched and ignited, if the "hot start" function is activated in the welding machine, the welding current should temporarily increase by a certain amount. For different manufacturers, this value may vary: 5, 10, 15, 30, .... 100% of the set welding current. Some welding inverters have a fixed value for the hot start current and cannot be adjusted, professional equipment has the option to turn it off (when welding thin metals to avoid burns), there are inverters where the "hot start" can be smoothly adjusted from 0 to 100%.

What is "hot start" for?

Simply put, Hotstart helps to ignite bad electrodes, when welding rusted metal, when the mains voltage is insufficient, for uniform penetration and in many other cases. It is best if the welding inverter has an adjustable hot start and you can adjust it yourself depending on your needs.

What is ‘’Arc force’’ for?

Arc force - Arcforce or Arcforsing are also identical

concepts. If the instructions for the welding machine indicate that this

function is present, it means that during the welding process, when the welding

arc "breaks" and goes out for some reason, an additional increase in

the welding current surge occurs. For example, if we have a welding current of

150 amps, when the arc breaks, the welding inverter adds more amps to that 150

amps to prevent the arc from going out. The meaning of the Arcforce (arc-force)

function is very similar to "hot start", only the increase in welding

current does not occur at the moment when the electrode touches the metal, but

during the welding process, when it is possible to break the welding arc. In

some welding inverters, this function is automatic and cannot be adjusted. Best

of all, you can adjust the “arc strength” by setting a value that will be more

comfortable and convenient for the welder.

What is Antistick, or electrode against sticking? What for is this feature?

Contrary to the common belief that the anti-stick function, Antistick prevents the electrode from sticking during welding - this is not the case. Electrode sticking is prevented only by the Arcforce function (arc-force), which we talked about earlier. When the electrode sticks to the metal, the welding current begins to pass through the electrode much more than the nominal one (i.e., the "short-circuit" mode practically occurs), as a result of which the electrode heats up. , and then it cannot be torn off from the workpiece, and further welding with this electrode is impossible, because all or part of the coating will peel off from it. If the welding machine has a built-in "Anti-stick" option, when the electrode "sticks", the welding current and voltage are reset to "0" and the electrode can be easily removed from the workpiece and welding can be continued conveniently using the same electrode. In some welding machines, the "anti-stick" can be controlled by adjusting it over time or turning it off completely.

Welding equipment offer in the store!

A reliable supplier for professionals and amateurs with a wide range of products, quality service, a convenient ordering system and prompt deliveries.

Shop INDUSTAR.LV offers its customers a wide range of different tools, such as power tools, hand tools, auxiliary materials, metalworking machines.

We are constantly adding new products from the world of metalworking to our assortment. All kinds of welding equipment, MIG / MAG, TIG and MMA, welding helmets, welding consumables. plasma cutters. At the request of our customers, we also begin to offer products related to home renovation, i.e. heating, plumbing and electrical products.

No comments

Leave a reply

Cart

Cart is empty.