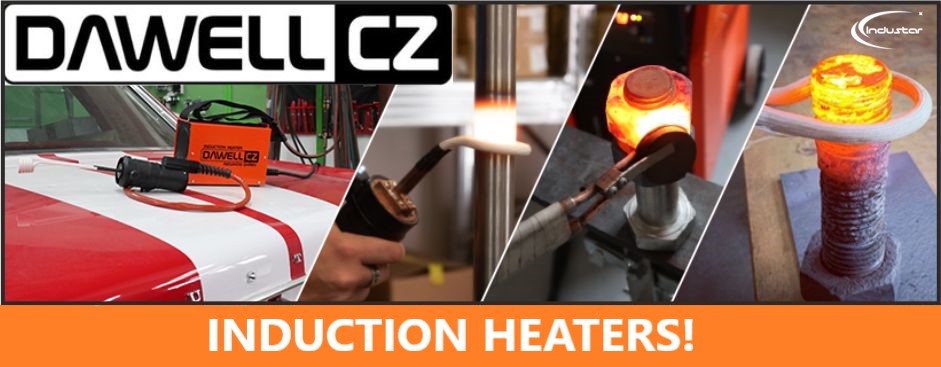

DAWELL CZ Induction heaters!

Induction heating is a technology suitable for heating a conductive object (usually metal) by electromagnetic induction through heat generated by eddy currents in the object. It is a non-contact method of heating objects that absorbs energy from a changing magnetic field created by an induction coil.

The actual working part of the device is the coil or inductor, and here the energy is transferred from the power supply and work head to the heated material.

The basic energy source is alternating current from the network (50 Hz), which is adjusted to the desired frequency of induction heating from 10 - 400 kHz in the power supply unit - inverter. Lower frequencies are used for larger objects for deeper magnetic imprinting, higher frequencies for thin-walled and small objects.

Induction heating is used for heating various materials and shapes before or after welding, straightening steel profiles, soldering, annealing and melting metal materials, all of which are used in various industrial and repair applications.

The main advantage is energy saving, as the material is heated only directly at the heat point without significant thermal influence of the surrounding environment. Operation and maintenance is very simple compared to other conventional flame heating methods.

Go to e-shop!

CATALOGS:

Induction heater DAWELL DHI-15 PKW-Must be in every workshop!

No comments

Leave a reply

Cart

Cart is empty.