Organization of the work of the welding shop!

Any welding shop is a difficult object. To organize it, you will have to coordinate with the fire brigade and the sanitary and epidemiological station, because first of all there will be energy in its pure open form, and this is electricity or fire from a gas burner.

Secondly, for the same reasons, there will be difficult working conditions. Therefore, it is very important to study the rules of organizing the workshop, strictly follow them throughout the operation of the welding section.

With what to start?

The design of welding workshops is extremely important. What is it? Here are several positions that will determine the technological process associated with welding, as well as the assembly of components and parts.

First, you need to deal with the packaging. It is clear that the main equipment of a welding workshop is welding equipment (gas, electric). Their cost is determined by the amount of work performed.

If the volumes are large, it is better to buy professional devices. If the welding workshop is small, you can buy a less well-known welding manufacturer, an analogue of a professional and expensive one. The welding shop needs to be diversified in order to collect as much work as possible, so it is worth considering the purchase of a contact welding machine.

One should not forget about at first glance simple devices, which will occupy a certain place in the welding shop, in the workshop. For example, a workbench or a table designed for welding.

It should be properly organized not only for the convenience of welding operations, but also for quick access to additional tools and consumables. In addition, the welder's workplace is a single set of devices that are used every day.

Placement of equipment and work tools!

The arrangement of equipment is strictly regulated by norms and safety rules in welding workshops. The layout determines safety, ease of movement of personnel, movement of parts, assemblies and finished products. There are several suggestions for arrangement:

if a transformer is used for electric welding in the workshop, it should be installed 5-7 m from the workbench and half a meter from the wall (minimum). A household inverter can be installed on a tabletop;

if welding is done with gas, then oxygen and acetylene cylinders are placed at least 5 m apart. The same goes for propane equipment. The same distance between the welding place and the cylinders is maintained;

gas hoses, electrical cables are routed away from the passages to avoid walking on them. This is primarily a safety requirement and secondarily a way to preserve property and equipment;

a distance of 1 m is left between equipment, tables, cabinets and other bulky items for the convenience of moving people, transporting parts on trolleys.

The automatic welding machine needs more space. Its movement in the welding plant and access to it by contractors must be taken into account.

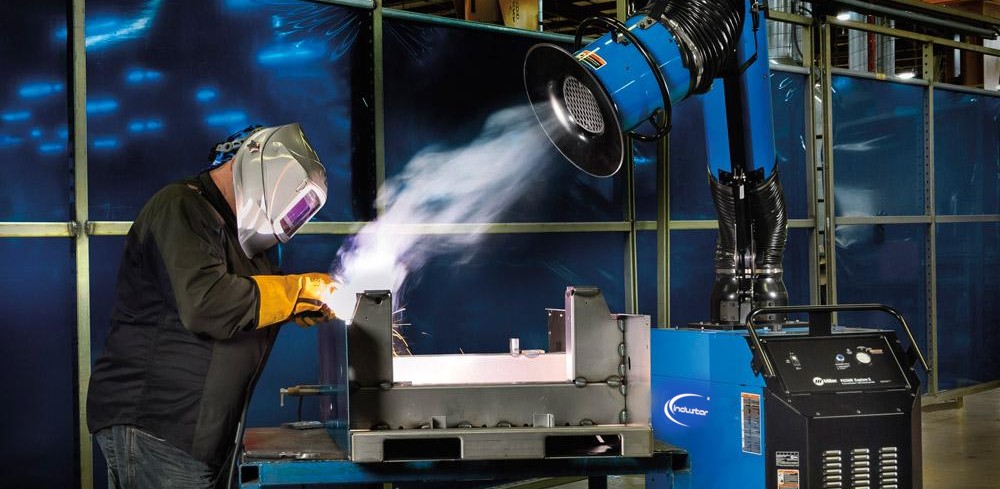

Ventilation system!

In the welding room, ventilation is the most important component and one of the main requirements for the organization of welding workshops. With its help, the heavy gases produced as a result of metal melting and burning of electrode rod coatings are removed from the welder's workplace.

Many people make the mistake of installing the probe above a large workbench that is connected by pipes or grooves to the general ventilation system. The best and most efficient option is to install a side outlet of the gases so that they do not rise above the level of the workpieces to be welded.

It is very important to make an accurate calculation of the ventilation system to ensure maximum air extraction from each workplace. The fan is best installed outside the workshop. This will be especially relevant if the welding workshop is organized in a garage or a small room.

A small room without ventilation will become a place where it will be impossible to do without a respirator or gas mask. And VVD will not give permission to operate such a poorly equipped workshop. Therefore, it is very important not only to install the ventilation system, but also to correctly calculate the characteristics of the fan, especially the power of the device.

In addition, divide the air ducts properly so that they do not obstruct the movement of large parts. This means that you will have to create a sketch, a drawing with the condition of the correct location of all system elements.

Requirements for premises!

In addition to all the above requirements, which are mainly related to safety, there are additional rules and regulations. One of the main ones is the strength and hardness of the floor in the welding shop. It must be finished and made of non-slip fire-resistant material.

Each welder must have his own workplace, the area of which is at least 2 m2. It is forbidden for two welders to work in it.

Although, if the welding workshop is small, then the workbench can be divided into two parts with one condition - a partition made of non-combustible material must be installed between the welders. It is usually made of sheet metal, or special welding shields are used.

The color finish of the welding shop is of great importance, especially when the processes are carried out with electric welding. Glare and glare can be distracting to workers. The main color of the paint is yellow, white or gray. As for the color, it is better to use zinc or titanium white.

Structural elements!

It is important to properly pay attention to the structure of the assembly and welding plant. If this is a manufacturing plant where various operations are carried out using a wide and varied range of materials.

Then, in addition to the main workshop, the production structure should include storage rooms: for metal, consumables.

In the procurement department, the metal is prepared for work: cutting to the specified dimensions, removal, grinding, etc. are carried out. Next, the products go to the intermediate warehouse, where the blanks are collected by position.

After that, everything goes to the main workplace, where parts and assemblies are assembled, welded into a single structure. The last department in the structure is the warehouse of finished products.

For obvious reasons, it cannot be organized in small welding workshops, but it is not necessary. For example, between the warehouse is useless here, the same applies to the procurement workshop.

As practice shows, all operations are usually performed in one room. And the finished product is stored either on the street under a shed, or is immediately handed over to the customer.

Description of the structure with warehouses - a rather large complex that can be located under one roof or in different buildings. In such circumstances, you cannot do without a well-thought-out logistics organization that allows you to save on vehicles.

In new industries, welding shops are trying to be arranged according to the block or module principle. The entire structural chain is on the same line with the necessary sequence of movements, from raw materials to finished products.

The attitude of consumers towards welding shops is almost unequivocal - this is a dusty room where people work in dirty overalls. But you shouldn't think that way about all workshops.

The new requirements and regulations reflect a new approach to a competent work organization, where, first of all, a person, his professionalism, the conditions in which he works are at stake. The result largely depends on it.

SIA Industar is an industrial goods trading company whose goal is to provide the best to its customers and ensure a full-fledged sales process.

We have selected a high-quality offer of goods from the best manufacturers, of which we are sure of the quality, technology and price of the goods! SIA Industar's offer includes both everyday goods for amateurs and professional companies - a wide range of tools and equipment for everyone.

SIA Industar has created a convenient product ordering system - an online store where everyone can view and purchase products.

We serve both individuals and legal entities. Both groups of customers increasingly appreciate the opportunity to purchase the necessary goods by ordering them electronically - online or in online trade from reliable professionals:

Our team will provide professional advice both in the selection of products and in the installation and use of equipment.

We will request payment for the goods only if we are sure of our ability to deliver the goods in the time you need.

For the delivery of goods, we use a courier service - package services to ensure prompt delivery of goods.

We are very responsible towards our customers and want to provide the best service!

Please contact us and follow our activities on social networks.

We wish you a positive online shopping experience with us!

No comments

Leave a reply

Cart

Cart is empty.